The first solid state portable audio recorder?

When trawling through an old backup of the hard drive of my Amiga 1200 I found a couple of audio files that took me straight back to the 90's, back to the time when I was a student and working as a trainee for Maycom Automation Systems BV in the Netherlands. The reason for this flash-back was that these audio files had been recorded on a Maycom Digicorder, one of the broadcast audio products Maycom released at the time.

When I subsequently searched the Internet to see if there was any information on the Maycom Digicorder, pretty little actually turned up. To be fair, there was no reason for me to expect a lot of information on the web; the recorder was introduced and discontinued again before the company operated their own web site, so even the WayBack Machine has no web based information on it. The Wayback machine did find a 1997 short article in a Polish audio/video magazine, but that is about all I could find.

To find nothing at all was a disappointment for a device that (to my knowledge) was first in class: the first solid-state portable audio recorder. At the time of its introduction it also received the Peter Wayne award of innovation from the International Trade Association for the Broadcast & Media Industry. For these reasons I think the device should not be forgotten, so I dived into my old archive of Maycom memorabilia and placed it here to ensure that there will be at least some information on this ground-breaking device to be found on the Internet.

At this moment I do not own, or have access to, a Maycom Digicorder. I would like to have access to one, even if it is only to create a couple of good quality pictures for this article. Please do get in touch if you can assist me with this.

Automating radio broadcasters

At the time I joined Maycom as a student (early 1994) the company's main product was a radio automation system called VAMOS, which tied all facets of radio broadcasting together with the help of a networked computer system. Not much can be found about VAMOS on the Internet nowadays either, but at the time it was used by a number broadcasters across the world, including national broadcasters like RTE and SABC.

The name VAMOS stood for "Video and Audio Manager on Optical Systems". At the time no video was supported, but this was planned to be implemented later down the line. The earlier versions of the system used Magnetic-Optical storage, which is where the "Optical Systems" part of the name hails from. Later implementations used standard hard drives as these had become cheap enough and (more importantly) large enough to store large amounts of audio.

Lots of storage for audio was necessary since the VAMOS system incorporated a large database of all the music a radio station might need. This database was used by the producer of a show to create playlists. During a show the "Play-Out" system would play the selected music directly from hard disks where the on-air presenter only needed to press a button to start the next item on the playlist.

An important element of the VAMOS system was the "Newscollector" that allowed journalists and reporters to file news items. These items could then be curated by editors,who could use the "multi-track editor" to create sound clips. These sound clips were then used by the "Play-Out" system to be used as part of the (news) broadcast.

Field recording

The standard method for a reporter to generate sound clips at the time was making a recording on location by using a portable cassette recorder, or tape recorder. After making the recording the reporter then had to come back into the radio studio to either edit the tape or to give it to an engineer for editing.

Radio stations using the VAMOS system still needed to play the tape back and record it on a computer so that it could be ingested into the Newscollector. This required the reporter to come back to the studio to either drop the tape off, or to record it into the system. Additionally the playing back of the recording happened in real-time, which meant that an hour worth of interview would take an hour to be ingested into the system before it could be edited.

The people at Maycom realised that a digital recorder would be able to fix both issues for the reporter; ingesting a digital audio file into the Newscollector would take mere seconds, but even better - a digital audio file could be transferred via ISDN or modem so that the reporter does not actually need to travel back to the studio in order to file the recording.

The prototypes

The first prototype of such a digital recorder was a large box which contained a mixing desk, a monochrome touch screen and a Windows 3.x PC that could run the full VAMOS audio editing suite. It was too large (and heavy) to be seen as a real portable solution, but worked very well as a study into the functionality required for the end design of what would become the Digicorder.

After the large editing box another prototype was built, this one meant to be a more accurate presentation of the intended device. This prototype worked as a physical study into the ergonomics of the design including the number of buttons and size of display.

The photograph below shows both prototypes:

The Digicorder

The official market introduction of the Digicorder was at the 1994 International Broadcasting Convention (IBC) in Amsterdam. To mark the occasion Maycom organised a launch event in one of the conference rooms of the Amsterdam Mercure hotel. Here the Digicorder was unveiled in front of an audience of dealers, distributors, press and important clients. All engineers and sales staff ware at hand as well as one ex-trainee (my traineeship had ended in July, but the company invited me to the event. I was obviously of not much use fielding questions, but enjoyed being there).

For its recording medium the Digicorder used PCMCIA cards, for which it had two slots. These were situated on top of each other on the left hand side of the recorder. The top slot was a Type-III slot, the bottom slot was Type-II.

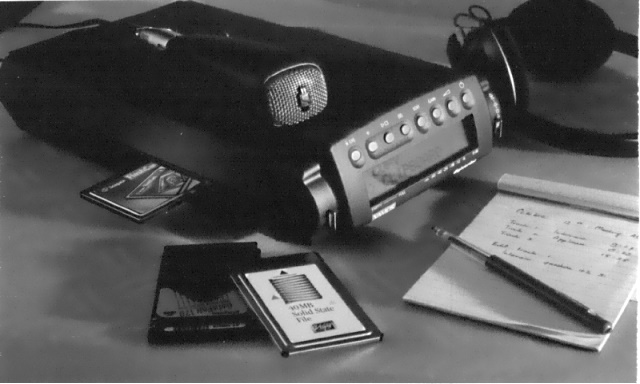

The photograph below shows an early picture (that I also found in the same Amiga backup) of the Digicorder. The cards in front of the machine are a Type-III 170MB hard drive (yes, spinning rust) and a Type-II 40MB Eiger flash card. Please note that the card sticking out of the machine has not been pushed in all the way; when inserted properly it will be completely inside the machine.

With its 2.5kg weight the recorder was heavier than a simple audio cassette based field recorder, but lighter than the tape based field recorders. Since the Digicorder's audio quality as well its price rather matched the tape based recorder, for the user this meant a lighter load rather than a heavier one.

Some of the unit's weight was caused by the heavy-duty plastic, named Nyrim, that the case was made off. To try out the sturdiness of the case, the owner of Maycom ran his Chrysler Saratoga over one of the cases and found out that the case indeed stood up to the test. Unfortunately a repeat of the test at a much higher velocity did indeed deform the case, which meant that the bent case from then on would be used as an exhibit on trade shows. There were always people coming to our stand to see the recorder that you "could drive with the car over it" [sic] as the story was always told.

The unit's main power source was a standard rechargeable battery pack, of a type that was widely used by various brands of battery powered DIY tools. This saved Maycom from having to design and manufacture their own battery packs, but also allowed the end user to buy their own battery packs and chargers while out in the field. The unit could also be powered via a mains power supply or a 12V car power supply.

For communication purposes the unit was given a built-in ISDN terminal adapter (TA), which supported European as well as American protocols. Initially the TA was only used for file based transfer, but later on real-time live audio connections with ISDN audio codecs was added.

Using PCMCIA cards for the recording medium also opened the door to other uses of the PCMCIA slots. Since the Digicorder had two slots it was possible to use one slot for the card with the audio recordings and use the other slot for communication devices. Eventually the unit's firmware would support standard POTS modem cards as well as cards that allowed a GSM phone to be used for audio file transfer back to the studio.

Speaking of the firmware, the unit had two versions of the firmware on board. One version was in a ROM, the other was stored in Flash memory. On power-up the unit would check the Flash memory firmware and start that when all was fine. Otherwise it would run the ROM version. The firmware in Flash memory could be updated by placing new firmware files on the PCMCIA recording media, which were then used to re-program the Flash memory. This allowed users to update their units while in the field. Having firmware as a backup in ROM gave protection to users accidentally interrupting the update process before it finished. For example by removing the mains power while no battery was installed.

The image below shows the user-facing part of the Digicorder. All controls are concentrated on the front of the device, which typically would stick out from something like a specifically made shoulder-bag. The buttons were designed to be weather proof and to be operable for people wearing thick winter gloves. Also visible is the "VAMOS" logo on the left hand side directly under the display, on later photos this logo will either be covered up or edited out.

On the right hand side of the unit is the jog shuttle with the jog wheel inside it. Both are used to provide an up/down interface, which is used for volume and gain up/down as well as menu navigation and scrolling through audio. The shuttle is spring loaded and will always return to the zero position. The further it is moved from this zero position the larger the up/down steps are, or, in case of audio scrolling, the faster the user is going through the audio. The wheel works in the same way and can be turned up or down and the faster it is turned, the faster the audio scrolling or up/down counting, similar to the use of a scroll wheel on a mouse.

The audio editor did very much mimic the operation of a tape recorder. The faster the user turned the wheel, the faster the audio was played back. Reversing the direction of turning would also reverse the direction of the audio. This allowed perfect accuracy to find any spot to cut the audio. Cutting was done non-destructively; the unit created an edit decision list (EDL) which told the unit which bits of audio to play and which bits to skip. This allowed for an easy "undo" function but also left the original audio recording completely intact. When transferring the resulting edit to the studio the unit would automatically assemble only the required bits instead of sending the complete original audio file accompanied by the edit decision list.

Working on the Digicorder

When I returned back to Maycom in August 1995 (this time as a full time engineering staff member) a lot of things had changed. The company was in the process of being split into two, with the VAMOS automation becoming a separate entity of the hardware division that was producing the Digicorder. From this moment on the unit was called the Maycom Digicorder and all links with VAMOS were removed. I was added to the hardware division as one of the (firmware) programmers. This doubled the number of programmers working at the hardware division as all the other software developers were leaving as part of the new company for the VAMOS product line.

After familiarising myself with the Digicorder's design my first major task was to re-write the audio stack inside the firmware. This stack was originally ported over from the VAMOS audio driver and while of a nice and flexible design it also contained a large amount of functionality that the portable recorder would never require. After poking around inside it I realised that I hardly needed anything from the big stack and decided it quicker to create my own from scratch. Within a couple of days I had created a proof of concept and in less than two weeks I created the new audio stack while my colleague converted the firmware in order to use it.

My colleague worked on the core functionality like the user-interface, file management and the audio editor. My domain was the communication side of things, first file transfer via ISDN and modem, later live real-time audio transfer with ISDN audio codecs like the CDQ Prima range of codecs.

Later on competing products started to be introduced, some of them at a similar price range and some of them cheaper. The Maycom engineers had not been idle either and had designed the Maycom Easycorder as the Digicorder's replacement product. The Digicorder was therefore removed from the price lists and subsequently discontinued.

Additional information

Part of my old archive of Maycom artefacts is a number of sales brochures from that period. I have scanned these and provide the links to PDFs of these scans via the links below:

VAMOS brochure (15MB) - Detailing the scope and use of the VAMOS system.

Digicorder flyer (3MB) - Handout flyer with Digicorder information.

Digicorder brochure (5.2MB) - Showing how the Digicorder can be used by reporters.

What's news 2 (4.1MB) - Exhibition hand-out showcasing the Digicorder

tech.jpg)